冰淇淋甜筒生产:集成 Optris 红外技术进行食品质量监测

使用 DewesoftX 软件自动化和优化冰淇淋甜筒生产中的巧克力涂层

Minimizing Waste and Maximizing Quality in Ice Cream Cone Production

An international ice cream manufacturer seeks to enhance the quality of its chocolate spraying process and automate the entire ice cream cone production line. With operations in over 20 countries, the company is a leading international distributor, offering various ice cream products, from classic cones to tubs and beyond.

In an automated ice cream cone production process, equipment mixes large batches of the mixture, ensuring consistent quality. Industrial freezing equipment maintains a continuous and efficient freezing process. Specialized machines mold the frozen mixture into cone shapes, while others sprinkle additional ingredients, such as chocolate or cream, onto or into the cones. Automated quality control measures ensure that each ice cream cone meets shape, size, texture, and flavor standards. Finally, automated systems package the ice cream cones into containers or wrappers at high speed.

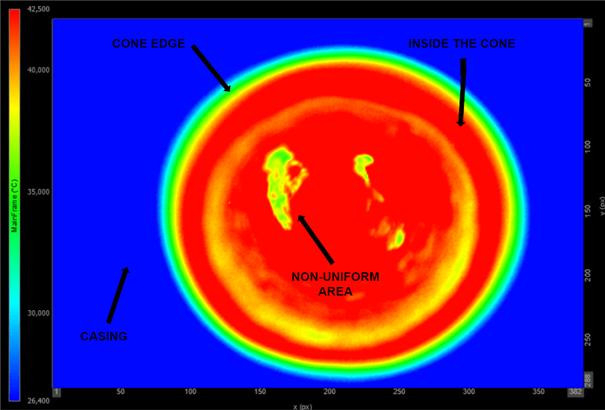

Many cones are covered with liquid chocolate during production, and various problems can occur during coating. During production, various problems can occur during the coating process. Incorrect machine settings can result in reduced spray pressure, leading to inadequate chocolate distribution. Material build-up can block nozzles, causing insufficient or no chocolate to be sprayed. Temperature fluctuations can affect the quality of the chocolate coating and the overall product. These issues can lead to high reject rates, resulting in significant waste and increased production costs. Automated quality control measures are essential to detect and address these problems promptly.

Pieces that do not meet quality standards are typically disposed of as waste. A machine malfunction generating non-conforming pieces can have significant implications for a company producing an ice cream cone every 1.5 seconds. If only 1% of the ice creams produced fail to meet standards, this results in 24 non-conforming pieces per hour. Over a 24-hour cycle, this amounts to 576 discarded ice creams daily. No company can afford such waste.

Infrared Camera Xi 400 Delivers the Thermal Input for the DEWESoft Software

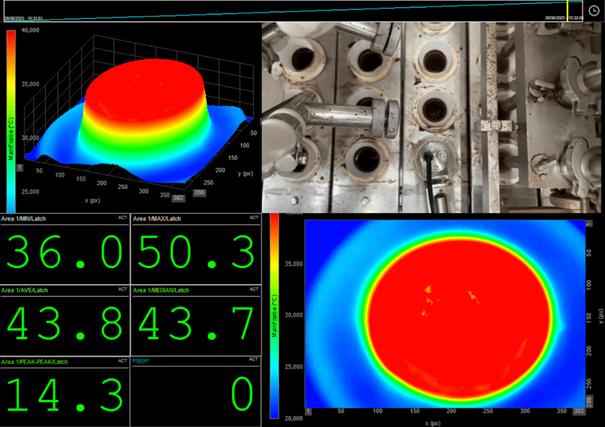

This advanced system utilizes an Optris Xi 400 thermal imaging camera, seamlessly integrated with DewesoftX software. The infrared camera connects via the Dewesoft Optris plugin, a software module that provides comprehensive data visualization, analysis, and storage support for various Optris thermal imaging cameras, including the Xi 400, PI 400i, and PI 640i models. The system specifically tests the efficiency of the chocolate spraying process, significantly improving product quality and automating the entire procedure.

A single thermal imaging camera with a resolution of 302 x 288 pixels is used to conduct these tests. Positioned at an elevated point above the production line, the camera captures crucial parameters for analyzing the quality of chocolate spraying on one of the six rows of cones at a time. The lens points downward to record the edges and inner areas of the wafers, ensuring precise data collection.

The DEWESoft solution records and compares average maximum and minimum temperature values. If the maximum value is too low and the minimum value too high, this indicates uneven chocolate spraying and potential nozzle issues. By continuously measuring and comparing the current temperature values of the ice cream cones, the system detects non-conforming parts. A specialized machine within the production process then automatically removes these defective parts, maintaining high product standards.

Accurate Thermal Data Collection and Easy Implementation with DEWESoftX

The Optris Xi 400 thermal imaging camera is selected for its robust and compact design, combining the durability of a pyrometer with the advanced functionalities of an infrared camera. Optris infrared cameras are perfect for system solutions that require quick and reliable temperature monitoring and the ability to trigger subsequent actions, such as alarms or automatic production line shutdowns.

These cameras are compact, robust, and adaptable, making them suitable for challenging industrial environments when used with available accessories. They integrate easily into existing processes and applications.

DEWESoft is utilized in the automation of the ice cream production line due to its advanced DewesoftX software, which offers comprehensive data visualization, analysis, and storage capabilities. The software seamlessly integrates with the Optris Xi 400 thermal imaging camera, enabling precise temperature monitoring and control. This integration allows for real-time detection of irregularities in the chocolate spraying process, ensuring consistent product quality. The robust and user-friendly solution enhances automation, predictive maintenance, and process optimization, significantly reducing waste and improving operational efficiency. Its adaptability to existing systems makes it an ideal choice for this application.

推荐产品

告诉我们您的红外温度测量需求

Optris 红外测温仪产品组合中有 300 多种不同的测温仪可供选择,每种都针对材料、光斑大小、与目标的距离和环境条件进行了优化。

Optris专业的工程师可以通过电话或线上指导您完成为红外传感器和红外热像仪产品的选购。